- +86 187 3271 1873/+86 132 8322 1383

- [email protected]

Investment casting, also known as lost-wax casting, is a highly efficient process used for producing complex metal parts with high precision. At Cencho, we specialize in customized investment castings that deliver exceptional dimensional accuracy, excellent surface finish, and reduced need for further machining. Ideal for industries like aerospace, automotive, medical devices, and energy, our custom castings meet the most stringent quality standards.

High Dimensional and Geometric Accuracy

Our castings provide unparalleled precision, often achieving tolerances as tight as CT4-6, ensuring a perfect fit for your applications.

Excellent Surface Finish

The surface of our castings achieves an exceptional finish, with Ra values ranging from 1.6μm to 3.2μm. This reduces the need for additional processing and improves the overall aesthetic and functional quality of the product.

Ability to Cast Complex Shapes

Particularly suitable for producing parts with complex shapes, fine features or thin-walled structures, such as turbine engine blades.

Wide Range of Alloy Compatibility

We offer a broad selection of alloys, including high-temperature, corrosion-resistant, and specialized materials. Our process can handle almost all metal materials for your casting needs.

The high precision and quality finish of our investment castings often eliminate the need for machining or only require minimal finishing. This saves time, material, and cost, while increasing production efficiency.

Aerospace: Such as jet engine blades, vanes, fuselage components, etc.

Automotive Parts: Such as turbochargers, engine blocks, fuel system components, new energy vehicle parts, etc.

Medical Equipment: Such as artificial joints, surgical instruments, and other precision medical devices.

Energy and Chemical Industries: Such as pump housings, valves, impellers, and other corrosion-resistant, high-temperature-resistant components.

Other Industries: Such as various hardware parts, electronic communications components, precision instrument parts, etc.

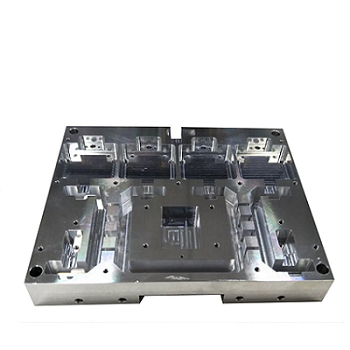

Mold Making Wax Injection Wax inspection Pattern Assembly

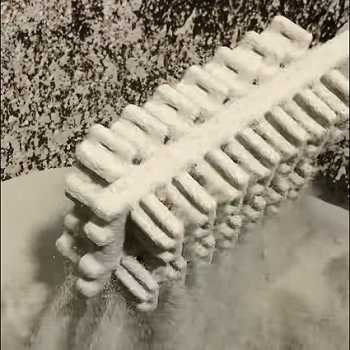

Coating Stuccoing Drying and Hardening Dewaxing

Mold Firing Pouring Knock-out Cut-off

Grinding and Polishing Post-processing

Our robust production capacity allows us to flexibly to customers' customized order demands.

We are capable of manufacturing customized products using materials such as stainless steel, alloy steel, high-temperature alloys, and aluminum alloys.

We provide highly competitive prices and relatively short delivery lead times.

In collaboration with our clients, we deliver professional services across the full lifecycle of product development and manufacturing.

We are equipped with professional testing facilities and are capable of providing comprehensive testing services for our products.