- +86 187 3271 1873/+86 132 8322 1383

- [email protected]

Process: Investment casting +CNC Maching

Application: used for pipeline of refrigerating system

Material: Stainless steel 304/316

Surface treatment: Shot blasting/acid pickling

Dimensions: Customized dimension

Products Description

Stainless steel precision casting, also known as investment casting or lost-wax casting, is a manufacturing process that produces highly accurate and complex metal parts by using a wax pattern. This technique is particularly well-suited for creating components with intricate geometries and tight tolerances from stainless steel.

High Precision: Capable of producing parts with very tight tolerances and detailed geometries.

Surface Finish: Provides excellent surface finish, often requiring minimal post-casting machining.

Material Versatility: Suitable for various grades of stainless steel, including austenitic, martensitic, and duplex stainless steels.

Complex Shapes: Allows for the creation of complex and detailed parts that would be difficult or impossible to achieve with other manufacturing methods.

Dimensional Accuracy: Ensures consistent dimensional accuracy from part to part.

This is a custom-made special flange, used for pipeline of refrigerating system, use investment casting and CNC machining.

It's surface requirements are very strict, must ensure the cleanliness of the inner surface.

Aerospace: Used for turbine blades, engine components, and other critical parts.

Automotive: Employed in the production of engine parts, exhaust components, and various structural elements.

Medical: Utilized for surgical instruments, orthopedic implants, and dental devices.

Industrial Machinery: Applied in the manufacture of pumps, valves, and other high-precision components.

Marine: Used for propellers, pump housings, and other corrosion-resistant components.

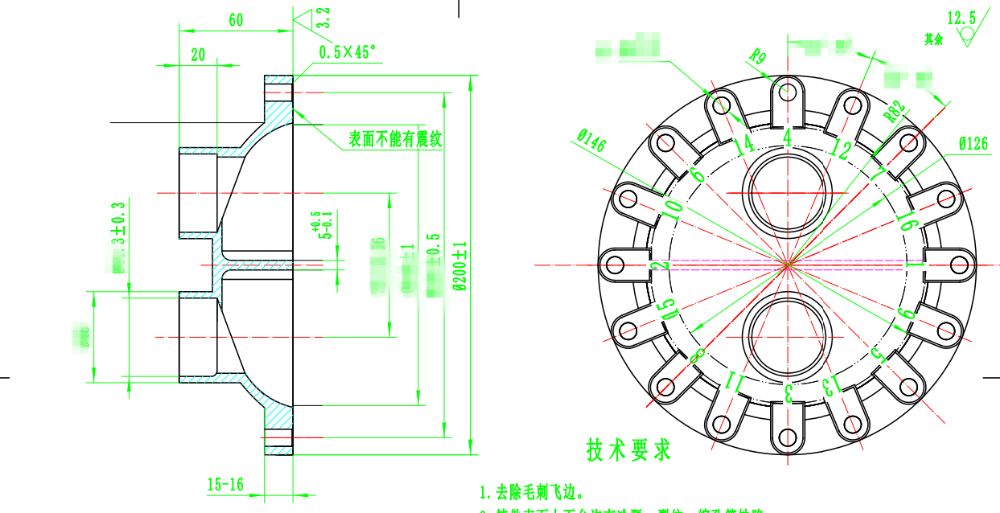

Custom-made Stainless Steel Special Flange Detail

Design Flexibility: Capable of producing complex shapes and fine details.

Material Properties: Maintains the desirable properties of stainless steel, such as corrosion resistance, strength, and durability.

Cost-Effective: Reduces the need for extensive machining, lowering production costs for complex parts.

Consistency: Provides uniform quality and consistency across large production runs.

Minimal Waste: Efficient use of material with minimal waste compared to other manufacturing processes.

Stainless Steel Precision Casting Flange Drawing

Pattern Creation: A wax pattern of the part is created, typically using injection molding.

Assembly: Multiple wax patterns are attached to a central wax sprue to form a tree-like assembly.

Shell Building: The wax assembly is dipped in a ceramic slurry, then coated with sand. This process is repeated to build a thick ceramic shell around the wax patterns.

Wax Removal: The ceramic shell is heated to melt and drain the wax, leaving a hollow ceramic mold.

Casting: Molten stainless steel is poured into the ceramic mold.

Cooling and Solidification: The molten metal cools and solidifies within the mold.

Shell Removal: The ceramic shell is broken away to reveal the cast metal parts.

Finishing: The cast parts are cut from the central sprue, and any necessary finishing operations (such as grinding, machining, or polishing) are performed.

Packing