- +86 187 3271 1873/+86 132 8322 1383

- [email protected]

OEM (Original Equipment Manufacturer) stainless steel anchor shank castings are specialized components designed for use in various types of anchors, primarily in marine applications. Our stainless steel castings provide high strength, corrosion resistance, and durability, ensuring reliable performance in harsh marine environments.

Hello,

We are in the marine industry and are introducing a new product. Last year we sold over 900 products/anchors.

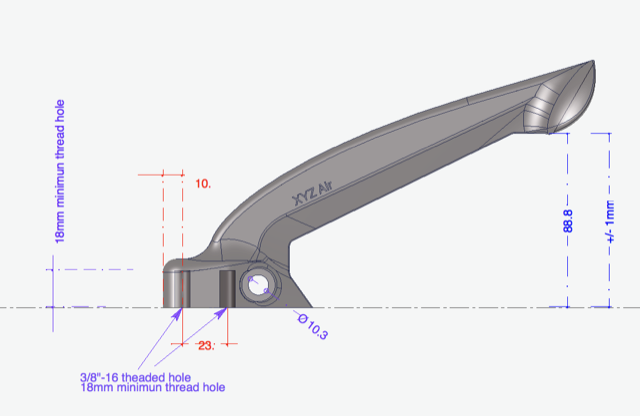

Enclosed are drawings, images, and 3D CAD files of the part-anchor shank that should be cast, with high precision in the 17-4PH stainless steel (H900 heat treatment). The surface finish should be high quality mirror/mirror hand-polished surface. The part is ≈ 0.600kg. The Shank must have a perfect surface finish with no scratches, small holes, and up-down/hill wave imperfections. The bottom surface with two (2) 3/8"-16 threaded holes must be grounded perpendicular and be perfectly flat! The two 3/8”-16 threaded screw holes must have clean threads so that the screws could be screwed in/out easily with fingers. The distance of 23mm between center holes must be done with high precision. The depth of the 3/8”-16 threaded holes should be 18mm minimum. The basic dimensions are in mm.

---------Above are the rough purchase information and technician requests from one of our American customers. Every time if want us to give an exact quote, customers all need to give us detailed information including material, CAD drawings, or 3D drawings which have the basic dimensions and machining or surface treatment requirements, later our technician will check all the information, study and find the fittest solution finally. If there is any feedback from our customer, we will also consider, and explain why we designed the process like this, for example why we chose stainless steel lost wax castings, not water glass craft or not machining process. or we will suggest which kinds of polishing method is best for his stainless steel castings combined his industry and application.

If unexpectedly we find the customer has a better idea on some link or his feedback is reasonable, because customers know more about their products, field, market, and application site than we, if there is the possibility, we will take customers' advice or will seriously take them into our considering of designing for the final manufacturing solution.

After all, we aim to satisfy and serve our customers maximally.

Stainless steel, especially grades 316 and 17-4PH, offers superior resistance to corrosion, crucial for marine applications where exposure to saltwater is constant.

High tensile and yield strength ensure the anchor shank can withstand significant loads and stresses during anchoring operations.

Stainless steel provides long-lasting performance, reducing the need for frequent replacements.

Can be polished and passivated to enhance corrosion resistance and improve aesthetic appeal.

We have a professional design center, technical service center, and fully automatic production line, specializing in providing customized services for customized precision castings, please contact us.