- +86 187 3271 1873/+86 132 8322 1383

- [email protected]

We have specialized in manufacturing all kinds of stainless steel casting parts for many years, our major craft is silica sol investment lost wax casting, In recent years we also brought in another cost-efficient technology---water glass, water glass is better for carbon steel, but if customers have strict requests for the surface roughness, we suggest you choose silica sol investment lost wax technology.

Although we are good at making all kinds of stainless steel material casting, if your material is carbon steel or brass, we also can do the casting and machining for you. Customized brass casting involves creating specific components or parts made from brass according to unique specifications provided by a customer. This process is commonly used in various industries such as automotive, plumbing, marine, decorative arts, and electrical applications due to brass's favorable properties, including its corrosion resistance, machinability, and aesthetic appeal.

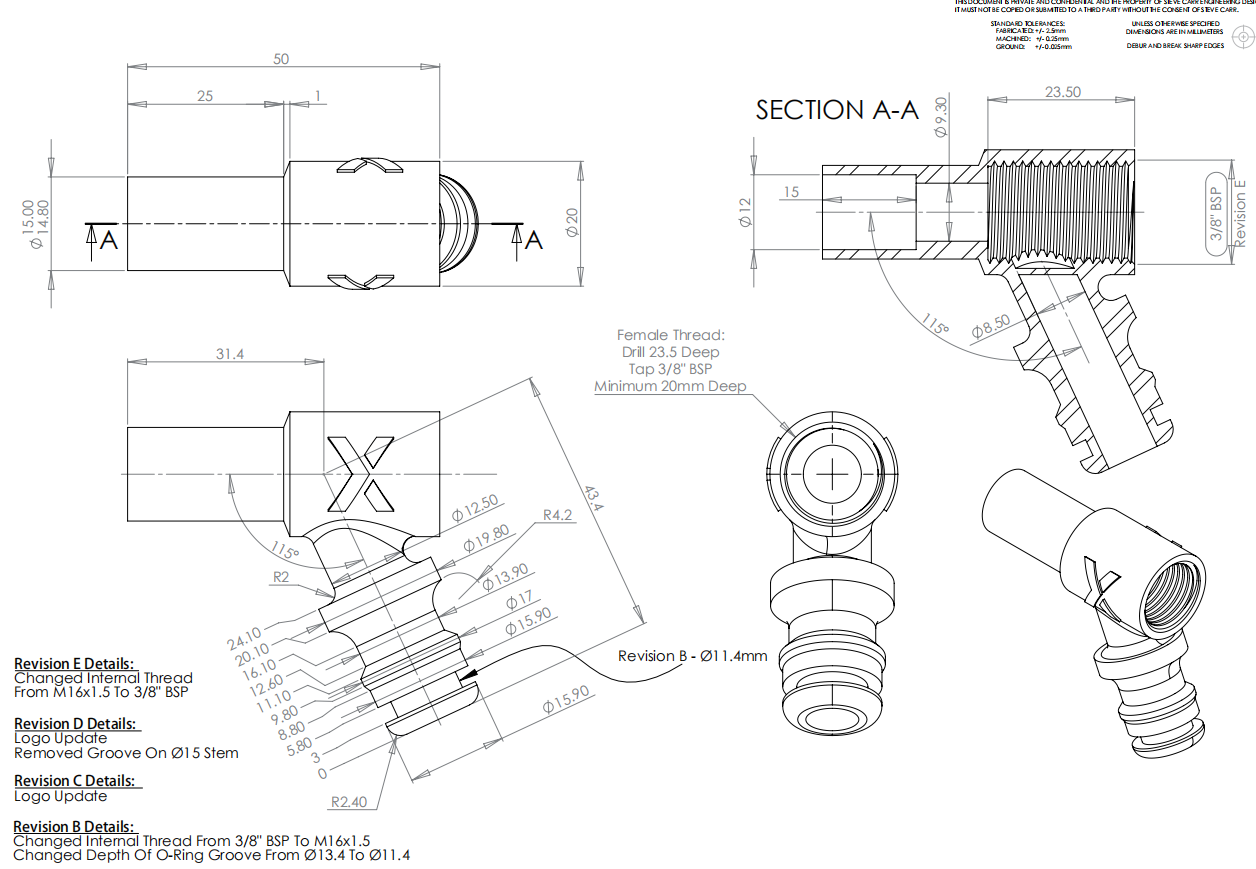

In this case, at first, the UK customers send us his pictures and drawings as below:

But just by those pictures, we can not know the exact weight and detailed sizes of each part, so we asked the its drawings again.

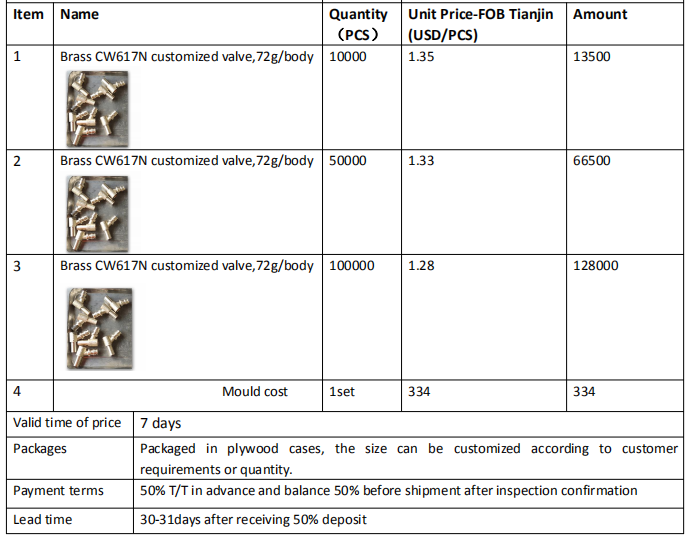

With all the above information, then we give out a precise price for that time.

Normally our quote will be related to the complicated degree of customers’ customized parts and the order quantity.

Create a detailed design based on customer specifications. A pattern is then made from the design, which can be in the form of a 3D model or a physical prototype.

The pattern is used to create a mold, typically made of sand, plaster, or metal. The mold includes cavities where the molten brass will be poured.

Brass is melted in a furnace to the appropriate temperature. The molten brass is then poured into the mold cavities.

The molten brass cools and solidifies within the mold, taking the shape of the mold cavities.

Once cooled, the mold is broken away to reveal the cast brass component. Excess material and mold remnants are removed.

The cast component is cleaned, machined, and finished according to the desired specifications. This may include polishing, plating, or coating.

The final product undergoes quality inspection to ensure it meets the specified dimensions, mechanical properties, and surface finish requirements.

Please send us your customization requirements, we can provide you with various types of parts made of investment casting, such as valves, pipe fittings made of stainless steel or brass, etc. We also cooperate smoothly with other customers and have sufficient experience and support, so contact us today.